Tank Support Options

A metal tank sitting in water will corrode quickly and the integrity of the tank is lost. Chemicals that are abundant in oil and gas operations will also be present and will speed up the corroding and weaking process. We have two options for getting your tanks up and out of the standing liquid that does not involve a penetration through your lining membrane. One option that is time tested to work is tank rings. The tank rings are set and squared up then filled with pea gravel or 3/8 chip. The other option is poly urea coated tank bases whereas the cores are made from EPS or Urethane foam.

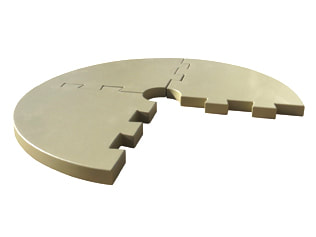

Interlocking Foam Tank Base |

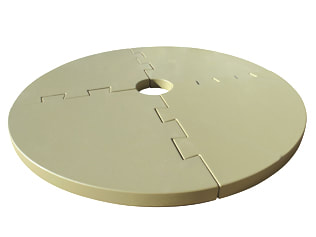

Tank Rings |

|

Foam core tank supports are light-weight and easy to install. The patented interlocking design offers identical parts meaning that you never get to to the job site with the wrong fit. Tough polyurethane coating is UV stable and corrosive resistant. Our unique design is easily assembled by a two man crew. Available to fit any tank size.

|

The time tested tank support method. Bands can be overlapped creating any size support. Tank bands are the lower cost method but time proven. No concerns of damaging tank rings during install unlike tank bases. Multiple heights available, can be stacked to create a taller base. Easy to level tank if needed by removing rock. Superior drainage.

|